Dielectric Coatings

Definition: thin-film coatings made of transparent dielectric materials, e.g. for laser mirrors or anti-reflection coatings

Alternative terms: thin-film coatings, interference coatings, multilayer coatings

More general term: optical coatings

More specific terms: anti-reflection coatings, mirror coatings

German: dielektrische Beschichtungen

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/dxh

Get citation code: Endnote (RIS) BibTex plain textHTML

Summary: This in-depth article on dielectric coatings explains

- what such coatings are used for,

- how they can be fabricated, and how fabrication details can affect the performance, and

- what criteria are relevant for the choice of substrate and coatings materials.

Dielectric coatings, also called thin-film coatings or interference coatings, consist of thin (typically sub-micron) layers of transparent dielectric materials, which are deposited on a substrate. Their function is essentially to modify the reflective properties of the surface by exploiting the interference of reflections from multiple optical interfaces. They can be used for a wide range of optical devices; some examples:

- anti-reflection coatings

- highly reflecting laser mirrors or partially transmissive output couplers

- dichroic mirrors (treating different wavelengths differently)

- various kinds of optical filters (e.g. for attenuation of certain wavelength regions)

- beam splitters

- heat reflectors

- solar cell covers

- thin-film polarizers

While simple single-layer coatings are often used as anti-reflection coatings, dielectric mirrors typically use dozens of thin-film layers, sometimes more than 100. A typical mirror design is the simple Bragg mirror, but there are many more sophisticated mirror designs.

Typically, a dielectric coating consists of discrete layers of two different materials (frequently some oxides such as SiO2 and TiO2) with substantially different refractive indices. However, there are also gradient index coatings for rugate filters, where the refractive index is continuously varied. This can be achieved, for example, by gradually varying the chemical composition of the material during growth. Also, there are coatings using three or more different materials.

In many cases, the coating substrate is a type of optical glass with a wide range of transparency and high optical quality (low bubble content), a very smooth surface (after proper polishing), and high durability. However, dielectric coatings can also be applied to crystalline materials, e.g. as antireflection coatings on nonlinear crystals for nonlinear frequency conversion and Pockels cells, or on semiconductor devices such as edge-emitting laser diodes, vertical cavity surface-emitting lasers, and photodiodes. Another area of increasing importance is the fabrication of dielectric coatings on polymers (plastic materials), as plastic optics are increasingly used due to their competitive properties, e.g. in terms of price and ease of fabrication of non-spherical surfaces, e.g. for aspheric lenses.

The material properties of the dielectric films can substantially depend on the used fabrication method (see below) and fabrication parameters such as the substrate temperature or partial pressures of various substances. Compared with the ordinary bulk materials of nominally the same chemical composition, thin-film layers often have a reduced packing density and a reduced refractive index. A common example is titanium dioxide (TiO2); layers of that can be deposited with different techniques, and the resulting density and refractive index depends substantially on the fabrication method. Low-density coatings also have a higher tendency of incorporating water, which implies performance changes depending on the humidity of ambient air and the device temperature. When designing a dielectric coating for fabrication on a certain coating machine, one should have the refractive index data for that machine under the used conditions, as the differences can be substantial.

Dielectric coatings are often applied to optical glasses, but they can also be used for plastic optics.

Designing Multilayer Coatings

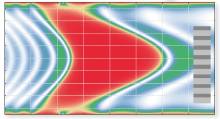

The reflectivity of multilayer dielectric coatings can be tailored to many different applications by using appropriate coating designs. A coating design includes the choice of dielectric materials (typically two different ones) and all layer thickness values. The articles on anti-reflection coatings and dielectric mirrors contains some details on design methods.

Fabrication and Choice of Materials

This section applies mostly to coatings for glasses and crystalline materials, even though some aspects also apply to polymer optics. The fabrication of dielectric mirrors is usually based on one of the following techniques:

This section applies primarily to coatings for glass and crystalline materials, although some aspects apply to polymer optics. The fabrication of dielectric mirrors is usually based on one of the following techniques:

- Electron beam deposition involves the evaporation of material in a crucible by heating with an electron beam generated from a hot filament and focused by a magnetic field. In the vacuum chamber, the vaporized material moves to the substrate, which can be covered with a mechanical shutter when the correct amount of material has been deposited. The target substrate is heated to a temperature as need to obtain high optical quality. (Thermal energy helps deposited atoms to find their proper location in the local lattice.) For typical coating materials, the resulting thin films tend to be somewhat porous, resulting in a reduced density and subsequently a reduced refractive index. The optical properties can then exhibit a significantly increased temperature dependence, as water can fill the pores and be driven out of the coating at elevated temperatures. This can be a problem for some sensitive steep-edge filter designs.

- A similar method uses evaporation by resistive heating of the crucible.

- Ion-assisted deposition (IAD) essentially works like e-beam evaporation, but with the addition of an ion beam (consisting of oxygen and/or argon ions) that strikes the target substrate. The relatively high energy of the ions allows rearrangement of the deposited material, resulting in denser coatings without heating the substrate. The method works well for oxide coatings (e.g. with SiO2 and TiO2), which can be of similar quality to those obtained with IBS (see below). However, IAD is not suitable for fluoride materials, which tend to dissociate.

- Ion Beam Sputtering (IBS) uses an ion beam that, after neutralization with a second filament, strikes a metal or metal oxide target to sputter material onto the substrate. The flux and energy of the ions can be independently and precisely controlled. IBS produces fairly uniform, non-porous coatings with good adhesion and very low surface roughness (possibly less than 1 Å), and is highly reproducible. However, it is relatively slow, requires expensive equipment and materials, and is less flexible than other methods.

- Advanced Plasma Reactive Sputtering (APRS) involves the sputtering of thin metal films, which are then oxidized in a separate oxygen plasma region of the chamber. Separate magnetron sources are used for different coating materials. APRS combines high precision and high density of coatings (similar to IBS) with high speed (comparable to evaporation techniques).

In any case, one starts with a homogeneous substrate material. In case of dielectric mirrors and AR coatings, that may for example be BK7 glass, fused silica, or CaF2. The substracte is often pre-processed by some method to produce a very clean surface. Common coating materials are oxides such as SiO2, TiO2, Al2O3 and Ta2O5 and fluorides such as MgF2, LaF3 and AlF3. The resulting layers are typically amorphous, with a density that can vary by more than 10% from the bulk density (depending on the deposition technique). Electron beam deposition typically produces materials with lower densities and thus lower refractive index. Such porous coatings have microvoids that can fill with water when exposed to humid air; in effect, the refractive index and thus the overall properties of the coating depend on humidity and temperature. Ion assisted deposition, and especially ion beam sputtering, achieves a higher density and thus a lower dependence on humidity. The optical damage threshold may also depend on the deposition method.

Materials with high refractive index contrast must be used for mirrors with high reflectivity, especially if a large reflection bandwidth is required. However, the chosen materials should also allow fabrication with high optical quality and high stability under given environmental conditions (regarding laser wavelength and intensity, operating temperature, humidity, etc.).

Important aspects for the selection of a processing technique are

- suitability for given coating materials

- the precision of the film thickness values (which can be increased by automatic control with in-situ growth monitoring)

- the optical quality of the deposited layers (influencing e.g. the scattering losses)

- the ability of the layers to withstand high optical intensity levels

- the uniformity of film thickness values over a large area

- the consistency (reproducibility) and stability of the obtained refractive indices

- the required substrate temperature

- the time required for growth

For example, ion-assisted deposition produces TiO2 films that are more compact, and thus more stable and homogeneous, and have a higher refractive index than e-beam evaporation, which is a faster process. The main reason for this is that TiO2 tends to grow in low density nanostructures, which can be destroyed (compacted) by irradiation with high energy ions.

In-situ growth monitoring is crucial to obtain precisely controlled film thickness values. One takes advantage of the fact that optical reflection or transmission properties can be used during the process to monitor the thickness of the currently grown layer, so that the growth process for a layer can be stopped at exactly the right time. One challenge is that the growth temperature is usually quite different from the intended operating temperature of the coating, and accurate temperature-dependent refractive index data are often not easily available.

Apart from the basic fabrication method, the process parameters such as the substrate temperature and growth rate can also be important for the quality. The details are often confidential proprietary information of the fabricators.

The requirements for the substrate material vary depending on the application. For highly reflective mirrors, the surface roughness can be important, but also the coefficient of thermal expansion (ideally similar to that of the coating materials) and the thermal conductivity. (In high-power lasers, residual absorption in the coating can cause some bulging of the mirror surface, leading to thermal lensing). For mirrors with partial light transmission (e.g. for output couplers of lasers, or dichroic mirrors), good transparency of the substrate in the relevant wavelength range is important in addition to high optical quality. The backside may have to be provided with an antireflection coating.

Dielectric coatings often exhibit a substantially lower threshold for laser-induced damage. That can also substantially depend on the fabrication method, including steps of preparing the substrate before deposition of the coating.

For antireflection coatings on laser crystals and especially on nonlinear crystals with anisotropic thermal expansion, but also for substrates with small radii of curvature or for optical devices exposed to some chemicals, it can be a challenge to obtain coatings that are sufficiently stable over a wide range of temperatures.

Bragg mirrors can also be made from crystalline semiconductor materials grown, for example, by molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) (→ crystalline mirrors). Such mirrors are often part of larger structures such as vertical cavity surface emitting lasers.

The article on dielectric mirrors explains in detail how the optical properties of dielectric coatings can be calculated and which aspects are important for the design of such structures.

More to Learn

Encyclopedia articles:

Blog articles:

- The Photonics Spotlight 2007-03-09: “The Trouble with Crystal and Coating Damage”

Suppliers

The RP Photonics Buyer's Guide contains 156 suppliers for dielectric coatings. Among them:

LASEROPTIK

LASEROPTIK can fabricate dielectric coatings with a range of methods including electron beam evaporation (EBE), ion assisted deposition (IAD), ion plating (IP), magnetron sputtering (MS) and ion beam sputtering (IBS). With our high precision machinery, we can produce accurate coatings for a wide range of wavelengths, substrate materials and applications. In addition to a large selection of from-stock optics, we offer coatings with refined custom designs.

IRD Glass

IRD is poised to serve all your coating needs, be it for the ultraviolet (UV), visible, or infrared (IR) spectral region. We have the ability to offer quick-turn basic coatings in-house. Our complete offerings run from basic MgF2 coatings to the incredibly intricate multiple-stack coatings, metallization and more. IRD offers HLDT AR and mirror coatings, ultra-high reflective mirror coatings, beam splitters, notch, BBAR and many more.

Avantier

Avantier is capable of providing a comprehensive range of dielectric coatings, including anti-reflective, high reflective, and partial reflective coatings. Our coating portfolio encompasses a diverse range of coatings, ranging from a single layer of anti-reflective coating to intricate multi-layer dielectric stacks. Our dielectric coatings come in various types such as BBAR, V-coatings, dual wavelength coatings, as well as sharp cut-on and cut-off filters.

EKSMA OPTICS

We offer dielectric laser mirrors for fixed, narrowband or broadband applications covering the UV, VIS and IR spectral regions. A wide range of round, elliptical or custom shapes as well as plano, spherical, cylindrical surface mirrors and substrates are available. Custom anti-reflection, high-reflection, partial-reflection dielectric coatings can be designed by qualified optical engineers and deposited in EKSMA Optics' advanced ion beam sputtered (IBS) coating facility.

Shanghai Optics

Shanghai Optics can provide all types of anti-reflective, high reflective, and partial reflective coatings. We produce a wide variety of coatings from a single layer of anti-reflective coating to complex multi-layer dielectric stacks. Types of dielectric coatings are BBAR, V-coatings, dual wavelength coatings, and sharp cut-on and cut-off filters.

UltraFast Innovations

UltraFast Innovations (UFI®) can design and fabricate various types of dielectric coatings, in particular those featuring a broad reflection bandwidth and controlled chromatic dispersion properties. Such coatings are applied to various optical components and can also be applied to components sent to us.

OPTOMAN

OPTOMAN concentrates on a single manufacturing technology – ion beam sputtering (IBS). We manufacture custom dielectric thin films for the 200 – 5000 nm spectral range. We are ready to develop cost effective yet advanced, high accuracy and repeatability thin film coatings optimized for your application. Our product range includes: laser line and broadband mirrors HR > 99.9%, R < 0.1% anti-reflective coatings, and thin-film polarizers with extinction ratio reaching 10000:1.

Focuslight Technologies

Focuslight Technologies produces dielectric coatings with IAD deposition. That includes anti-reflection coatings (from deep UV to the infrared), high reflectors, beam splitters and filters.

Perkins Precision Developments

Perkins Precision Developments (PPD) manufactures custom IBS coatings for laser mirrors, beam splitters, polarizers and other precision optical components for wavelengths from 300 nm to 3 μm. PPD utilizes Ion Beam Sputtering coating technology because it is ideal for complex spectral designs, high power Nd:YAG and fiber lasers and applications where it is critical to minimize losses from absorption and/or scatter. IBS thin films have densely packed micro-structures resulting in stable, easy to clean optics that are insensitive to environmental changes such as heat, humidity and pressure. Our coatings may exhibit damage thresholds of 20 J/cm2 or sometimes even 60 J/cm2 at 1064 nm.

Common coating types include high power high reflectors (HR), multi wavelength reflectors, low-loss anti-reflection (AR), dual-band anti-reflection (DBAR), dichroic and trichroic beam splitters, output couplers, low phase shift mirrors, dispersion controlled mirrors, edge filters, band-pass filters, polarizers and non-polarizing beam splitters.

Knight Optical

We offer a range of dielectric coatings for optimum reflectivity. Available for a variety of components including beamsplitters, front-surface mirrors and rod and cone mirrors, to name but a few, our dielectric options include visible, near-infrared (NIR), infrared (IR) (2000 nm +) and large parts (1000 mm).

Bibliography

| [1] | J. R. McNeil et al., “Ion-assisted deposition of optical thin films: low energy vs. high energy bombardment”, Appl. Opt. 23 (4), 552 (1984); https://doi.org/10.1364/AO.23.000552 |

| [2] | H. Sankur and R. L. Hall, “Thin-film deposition by laser-assisted evaporation”, Appl. Opt. 24 (20), 3343 (1985); https://doi.org/10.1364/AO.24.003343 |

| [3] | P. J. Martin, “Ion-based methods for optical thin film deposition”, J. Mat. Science 21 (1), 1 (1986); https://doi.org/10.1007/BF01144693 |

| [4] | C. Amra, M. Zerrad and M. Lequime, “Trapped light scattering within optical coatings: a multilayer roughness-coupling process”, Opt. Express 29 (16), 25570 (2021); https://doi.org/10.1364/OE.428326 |

| [5] | H. A. MacLeod, Thin-Film Optical Filters, Adam Hilger Ltd., Bristol (1986) |

| [6] | A. Thelen, Design of Optical Interference Coatings, McGraw–Hill (1989) |

| [7] | N. Kaiser (ed.), Optical Interference Coatings, Springer, Berlin (2003) |

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

photonic devices

photonic devices

Share this with your network:

Follow our specific LinkedIn pages for more insights and updates: